High pressure cooling HOFMEISTER / service

HIGH PRESSURE COOLING - COOLING WITHOUT COMPROMISE

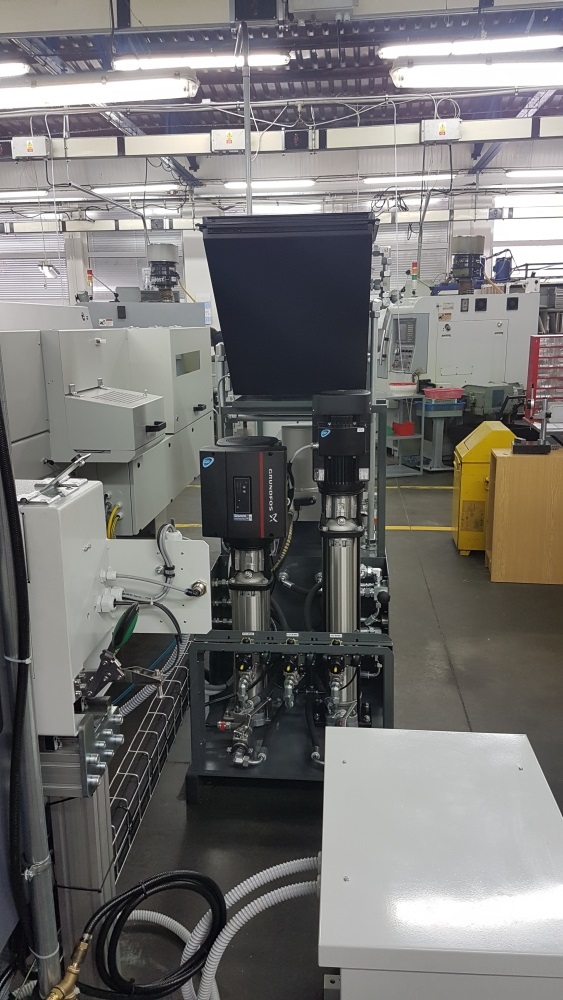

Hofmeister company offers sale, installation and service of HOFMEISTER high-pressure cooling systems.

High pressure cooling with added filter is a tool cooling system for metal machining with outer rinsing and internal cooling through the centre of a tool. It has all the necessary equipment to reliably supply machines working in continuous operation. It serves for filtration of working fluids, size of dirts ≤ 40 μm. Possible application when cutting steel, aluminium, titanium and copper

Reasons to buy high pressure cooling

- increase of cutting speed and feed

- increase of cutting tool durability

- tools do not get destroyed due to overheating

- it helps to break and remove chips and thus increase the reliability of the machining process

- it supplies the the cutting area with the correct volume of strong coolant flow

- high-pressure cooling system produces short broken chips

Technical parameters

- automatic high pressure units allow unsupervised operation

- outer cooling with rinsing of the tool Qmax = 40 l/min - pressure p = 10 bar

- internal cooling through the centre of the tool Qmax = 40 l/min - pressure p = 47 bar

- stainless automatic candle filter for separation of suspended solids from working fluids, flow rate to 100 l/min at 8 bar, filtration ≤ 40 μm. It is useful mainly for filtration of water dilutable liquids or cutting oils with a viscosity up to 13 mm²/s at 20°C

- fully automatic operation of the device, electronic scanning of fluid levels

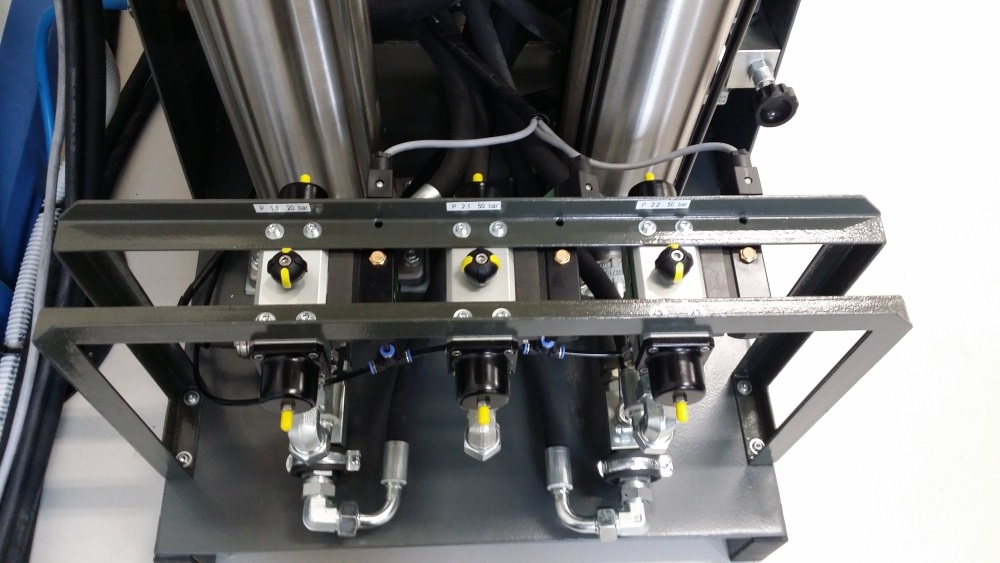

- air operated electric controlled exit servo valves that control exit cooling under the pressure up to 50 bar

- cooler of working fluid with possible temperature adjustment by means of the thermostat

- communication interface with machine tool, commands to pumps, alarm, breakdown of machinery

Machinery advantages

- smaller installation space - width only 0.65 meters

- filtration of mineral oils and synthetic fluids

- high pressure pump with frequency converter and sensor of gained pressure

- volume and form of the tank can be solved according to customer requirements

- colour version can be delivered in RAL colour shades on demand

- standard color is shade according to RAL 7043

- possible filtration of light and non magnetic metals

- automatic operation with minimum maintenance requirements

- stable filtration ability is reached by means of an automatic filter with maintenance-free regeneration

- minimal oil separation from emulsion

- fully automatic stainless steel filter with regeneration ability without using paper and textile filter cloths

- universal use of process liquids (mineral and synthetic emulsions, cutting oil)

- larger cooling capacity - up to 100 l/min at the same pressure

- all delivered Grundfos pumps are available with stainless steel hydraulics

- expandable up to 8x servo valves that control exit cooling liquid

- electronic level and pressure monitoring

- cooler used at higher cutting performance and the requirement to ensure a stable temperature of the cutting fluid throughout the whole machining process