Measurement & Control

We focus on complex, independent, custom measurement of machine parts. For measuring parts we use the latest measuring technology. We are able to perform a complete control of all part dimensions or only of dimensions important for your individual needs. Upon request we will also elaborate a statistical process control (SPC). We adapt the operation of our measuring center to your needs. Our company is bound by confidentiality regarding leakage of information about measured parts and their documentation.

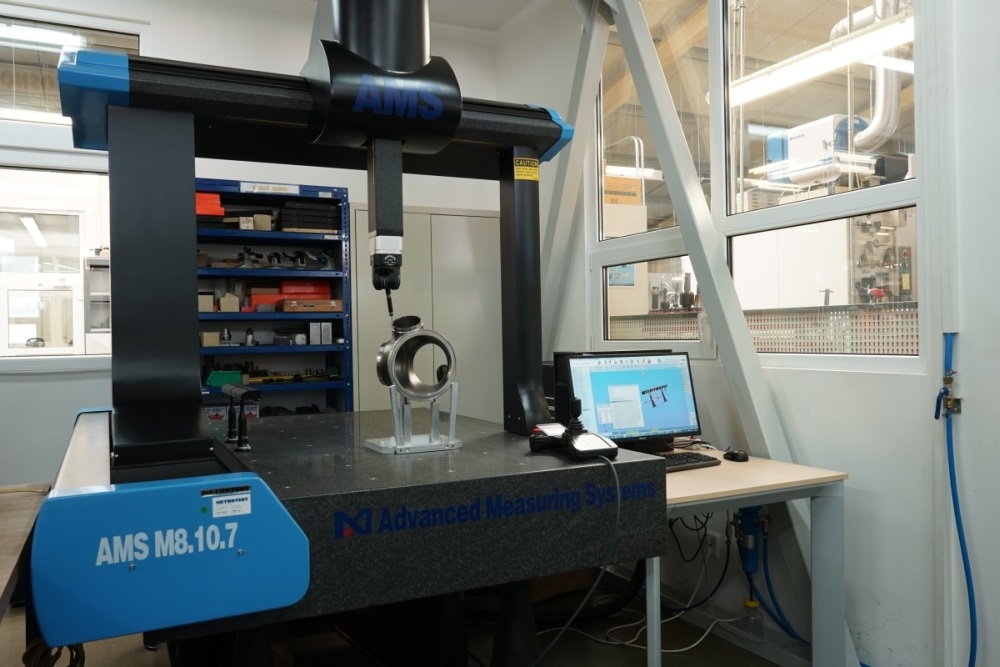

Machinery equipment

Service offer

- Measurement on coordinate measuring machines

- Consultancy in the field of measurement methodology and programming

- Statistical process control (SPC) - evaluation

- Optical measurement on Alicona microscope

- Optical and mechanical measurement of surface roughness

- Hardness measurement

- Measurement of cutting tool geometry

Coordinate measuring machines

We provide the service on cutting edge IMS (UK) a AMS (USA) machines that allow a very accurate complete measurement of dimensions and geometrical tolerances of a part according to drawing documentation. It is also possible to compare a part with CAD model of all common data formats. The output are graphical or text dimensional protocols. Both machines use RENISHAW hardware and control. Annual calibration is a matter of course.

Dimensions of the coordinate machine working space: X = 800 mm, Y = 1000 mm, Z = 700 mm

Specified accuracy tolerance: 0,0025 mm + L/300

Optical microscope ALICONA

Optical 3D scanner that will impress you not only with its accuracy (magnification up to 1000x), but also with its detection of the smallest surface details, which are often crucial for the correct function of the part. This system offers a combination of roughness and surface measurements. It is suitable for complex geometries with small radii and angles. Measurement of surface or profile roughness and geometry in hard to reach places (radius, bevel, thread).

Five-axis camera measuring machine ZOLLER

It serves for measurement of all geometries on cutting tools. The machine is equipped with a high quality 3D camera, which is used for measurement of three-dimensional elements of tool geometry. In combination with a 2D camera and a very precise clamping spindle, the machine comprehensively measures tool parameters with micrometer accuracy.

Digital measuring system KEYENCE

It is a programmable optical comparator, measuring microscope and profilometer. The main domain of this system is the speed of measurement. Therefore, it is often used for sorting identical and nonidentical products, or for measuring all pieces in a batch. Depending on the lens used, it works with an accuracy of up to ± 0.002 mm. The measuring range is 100 mm x 200 mm, maximum weight of a measured part is 2 kg.